The EV Mission

Design and build a fully functional, all-electric, EV car using sustainable production methods.

The Challenge – Full-Scale Functional Prototyping

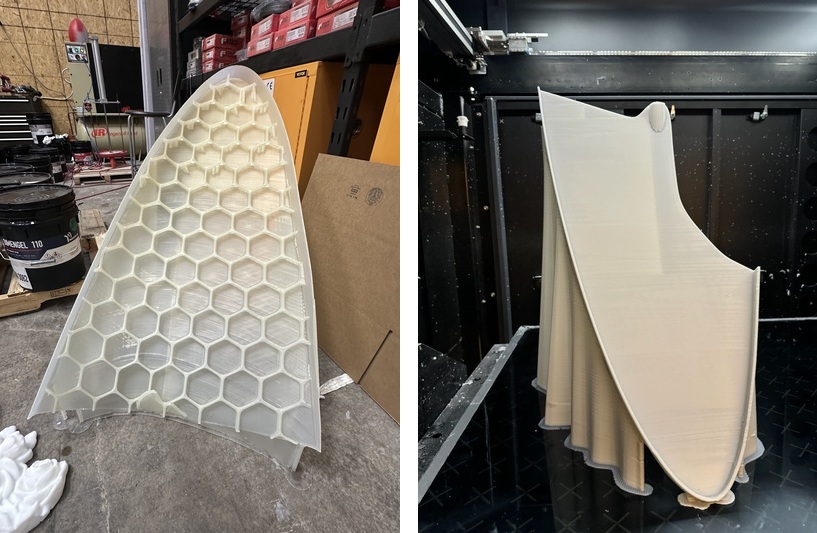

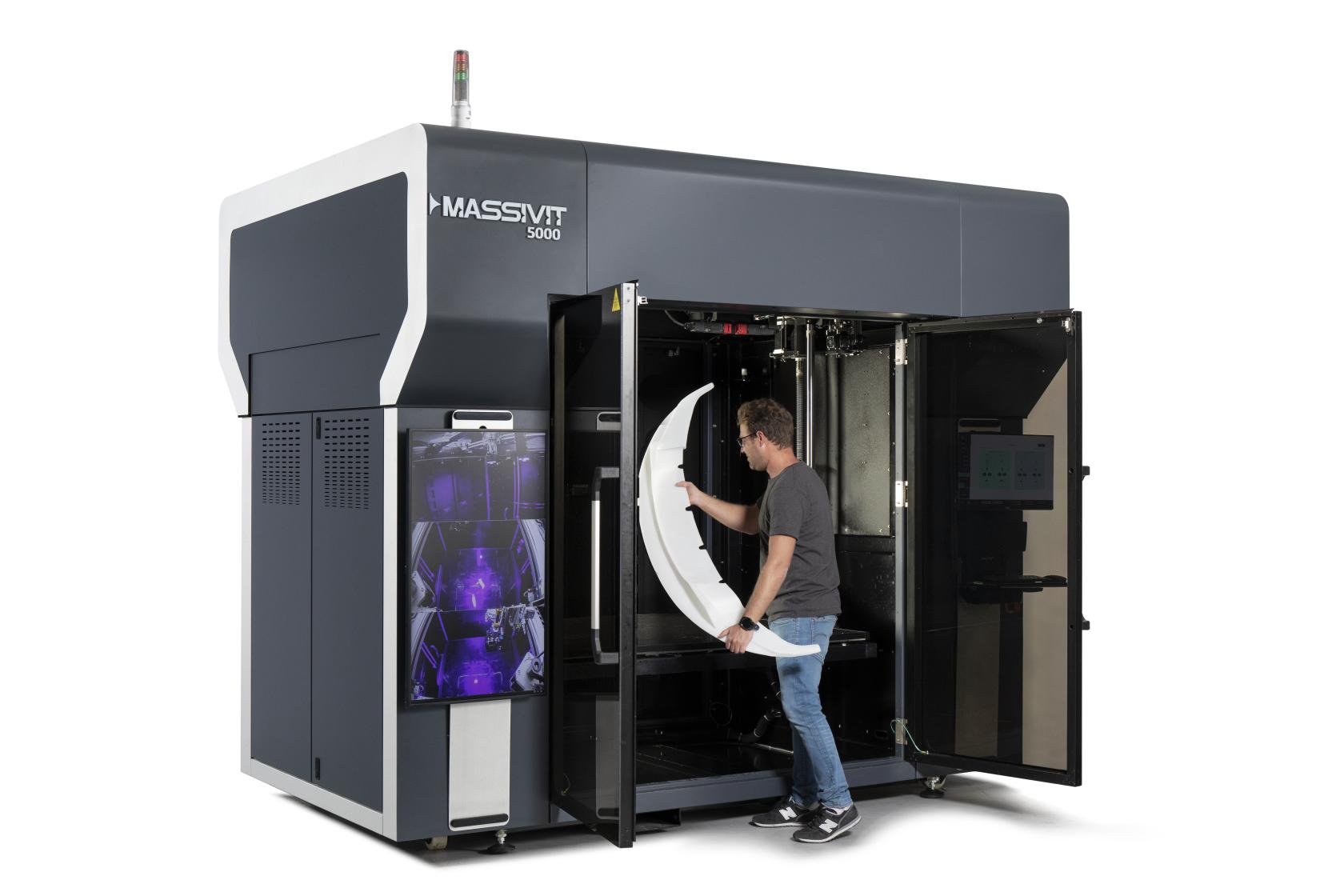

One of the challenges of transportation prototyping is building full-scale parts without the need to bond multiple pieces together. Industrial 3D printers allow large components to be printed in one piece. For instance, Massivit’s gel-based 3D printing technology uses UV light to cure large components on-the-fly while printing. This enables ultra-fast creation of full-scale components that can then be reiterated and quickly printed again within a few hours, as needed. Large car panels, train covers and truck grills alike can be produced with relative ease. The case study below explores how LSAM (large scale additive manufacturing) is serving faster design and development lead times as well as sleek new design possibilities.

The Players

Rafael Corazza Ronchetti, a former Lamborghini and Audi designer for Super Cars, is now a Professor of Industrial Design at SCAD (Savannah College of Art and Design). He teamed up with a SCAD crew of engineers to bring to life The Aether – an additively manufactured functional EV whose design is strongly influenced by the Ferrari 312 F1 and Porsche 917.

Ronchetti’s colleague, Owen Foster – SCAD Design Associate Chairperson, highlighted the fact that “Gen Z and Gen Alpha drivers are looking for something that will amplify their own unique journey through life.”

Solution – Fully 3D Printed EV Concept Car

The Aether – ‘God of the Upper Atmosphere’ – was manufactured with an entirely 3D-printed body. Custom Design Studio, Hatch Exhibits, partnered with the SCAD team to rapidly print the main car panels using a Massivit 5000 large-scale 3D printer. Based on Gel Dispensing Printing technology, this industrial-grade printer allows automotive design teams to produce any desired geometry based on CAD designs or 3D scans. Inspired by early Ferrari and Porsche models, the Aether is an elegant, convertible EV, designed to attract a younger demographic. It is a fully-electric battery-operated vehicle offering an AI dashboard to enhance the driver experience by matching music to specific driving patterns. The car has transparent internal paneling for tech-savvy enthusiasts.

Less is More – Sustainability Drives Production

Sustainability was a major driving factor for the SCAD team on The Aether. Their decision to create the full-size mockup with industrial 3D printers is largely based on the sustainability factor. Additive manufacturing by nature only uses the minimum required material, as opposed to traditional milling, machining, or clay methods which generate huge amounts of material waste. Moreover, 3D printers enable OEM’s and service bureaus to bring all production inhouse – meaning reduced transportation needs and reduced overall carbon footprint. Another major benefit for automotive manufacturers is centralizing the design and development inhouse in order to safeguard sensitive design IP.

Less of a Puzzle

The ability to print single big panels overcomes the old-age car manufacturing issue of having to bond multiple smaller parts together to make a 1:1 component. This enables greater overall design accuracy.

Elegance & Speed

The Aether was showcased in all its glory at the 2024 Formula 1 U.S. Grand Prix in Austin, Texas. Meeting the production deadline on time, not only did this masterpiece attract attention from car designers and aficionados, but it well-and-truly fulfilled the goal to build a fully functional, all-electric, car using sustainable methods.

Curious to discover large-scale 3D printing benefits? Reach out to us here.